Polyethylene tubes

Polyethylene tubes represent a versatile and functional solution for packaging various products.

These tubes are particularly valued in the cosmetic, pharmaceutical, and food sectors due to their ability to effectively preserve and protect the contents.

Available in three densities—HD / LD / LLD—that can be blended together to achieve the desired effect.

The polyethylene tubes produced by Global Tube® are extruded with capacities ranging from 5ml to 400ml in the 7 available diameters.

PE is a thermoplastic resin with excellent insulating properties and chemical stability, making it one of the most versatile materials.

Key features, common applications, and advantages of

polyethylene tubes

Features

Flexibility

The tubes are made of polyethylene (PE), known for its flexibility and strength. Global Tube® offers tubes in three different densities of polyethylene: high density (HD), low density (LD) and linear low density (LLD). These variants can be mixed to achieve the desired effect, both tactile and functional, according to the specific requirements of each product.

Capacity and Sizes

Tubes are available in capacities ranging from 5ml to 400ml.

This wide range of sizes allows different packaging requirements to be met, from test samples to larger sizes for regular use.

Available Diameters

Seven different extrusion diameters are offered, allowing for further customisation in terms of design and user-friendliness.

Applications

Cosmetics

Ideal for creams, gels, and lotions, thanks to their ability to protect products from light and air.

Pharmaceuticals

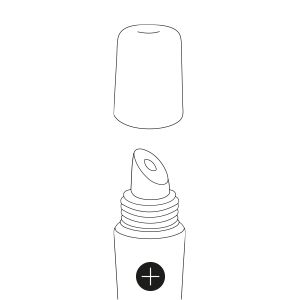

Used for medicinal ointments and gels, they offer precise and hygienic dosing.

Food

Perfect for products such as sauces and dressings, thanks to their compliance with food safety standards.

Advantages

Customisation

The possibility of choosing between different densities and diameters allows the tube to be adapted to the product and brand.

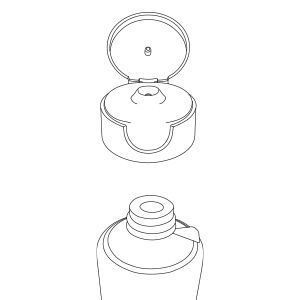

Ease of use

Polyethylene is a light and flexible material, which facilitates the daily use and transport of packaged goods.

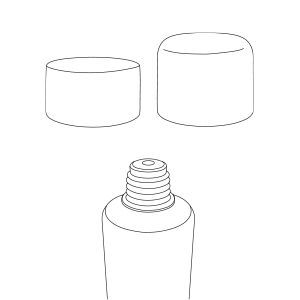

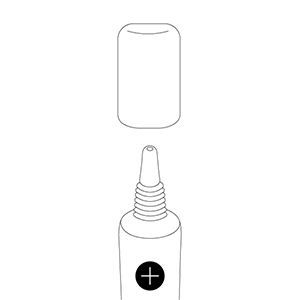

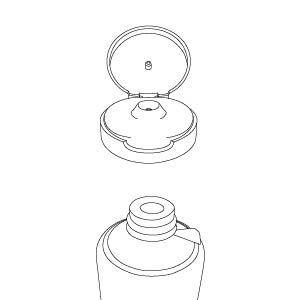

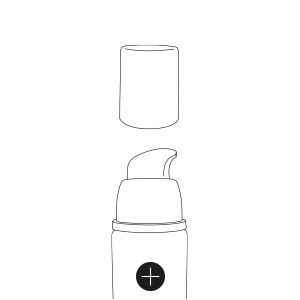

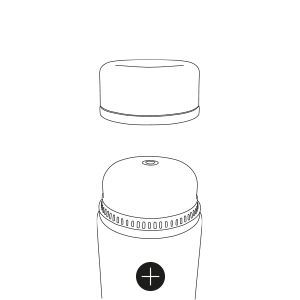

The polyethylene tube market is continuously evolving, with innovations aimed at enhancing product functionality and aesthetics. Advanced technologies allow for the incorporation of features such as sophisticated applicators and customised finishes that enhance visual appeal and user experience.

An increasingly important aspect in the selection of packaging materials is their environmental impact.

Polyethylene tubes are designed to be recyclable, contributing to the reduction of plastic waste. With the rising awareness of environmental issues, they also enhance brand image and meet increasingly stringent sustainability regulations.